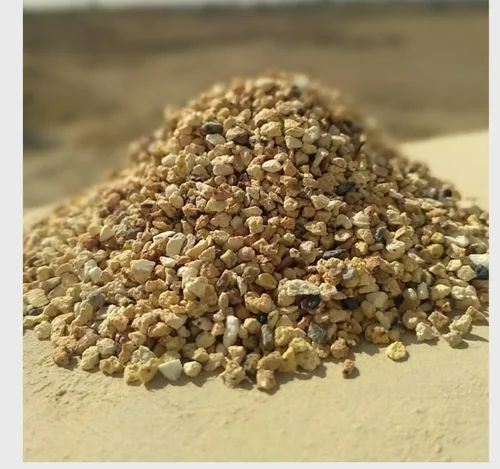

Refractory bed material

Refractory bed material is essential in high-temperature industrial processes, designed to withstand extreme conditions in fluidized bed combustion systems, gasification units, and similar applications. Its chemical composition typically includes alumina (Al2O3), silica (SiO2), iron oxide (Fe2O3), magnesia (MgO), and calcium oxide (CaO), providing excellent thermal stability, high melting points, and resistance to thermal shock and abrasion. These properties ensure durability, reduce maintenance costs, and improve energy efficiency in various high-temperature environments such as kilns, furnaces, and chemical processing reactors.

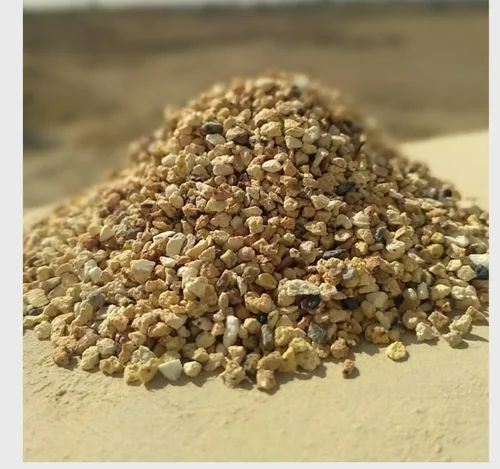

Refractory bed material

Refractory bed material is essential in high-temperature industrial processes, designed to withstand extreme conditions in fluidized bed combustion systems, gasification units, and similar applications. Its chemical composition typically includes alumina (Al2O3), silica (SiO2), iron oxide (Fe2O3), magnesia (MgO), and calcium oxide (CaO), providing excellent thermal stability, high melting points, and resistance to thermal shock and abrasion. These properties ensure durability, reduce maintenance costs, and improve energy efficiency in various high-temperature environments such as kilns, furnaces, and chemical processing reactors.

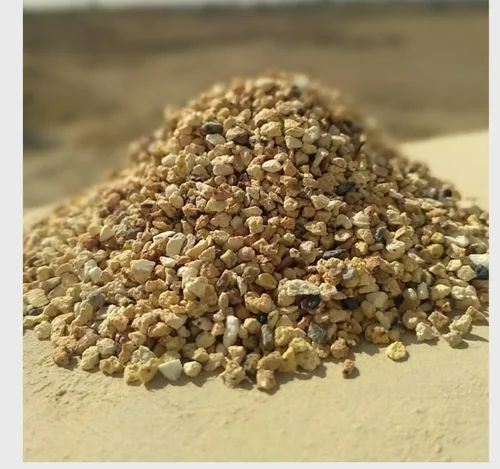

Building a Better Future with Refractory Bed Material

- Fluidized bed combustion: Enhancing combustion efficiency and reducing emissions with durable refractory bed materials.

- Gasification units: Ensuring reliable operation and longevity in gasification processes with high-quality refractory materials.

- Kilns and furnaces: Protecting against extreme heat and corrosion to improve kiln and furnace performance.

- Chemical processing: Providing thermal stability and resistance to chemical reactions in high-temperature reactors.

- Metal smelting and refining: Enhancing process efficiency and equipment lifespan with refractory linings.

- Incineration plants: Reducing maintenance costs and increasing operational reliability in waste incineration.

- Cement production: Improving kiln efficiency and product quality with refractory materials in cement manufacturing.

Join the Conversation: Contact Us

- Phone Number : 9978579512

- Email ID : Info@terramineral.in

- Office Address : B 11 Ground, Shalin Square, Lal Gebi Cir, Vinzol, Hathijan, Ahmedabad, Gujarat 382445